What Is Froth Flotation?

Froth flotation, also called ore flotation when used in mining applications, is a method for physically separating particles by having air bubbles that selectively adhere to specific surfaces. The particles with attached air bubbles are carried to the surface and removed.

Froth flotation is one of the most widely used methods for ore beneficiation. It is also used for wastewater treatment (where it is called Dissolved Air Flotation, or DAF) and in the deinking step of paper recycling. The following information focuses on mining, but the principles are the same.

In the mining industry, the plants where flotation is performed are generally known as concentrators or mills. The ore is ground and crushed into small particles and then mixed with water to form a slurry. The desired mineral is then made hydrophobic by the addition of a surfactant or a collector chemical (although some mineral surfaces are naturally hydrophobic). The particular chemical depends on the nature of the mineral to be recovered and, perhaps, the nature of those that are not wanted.

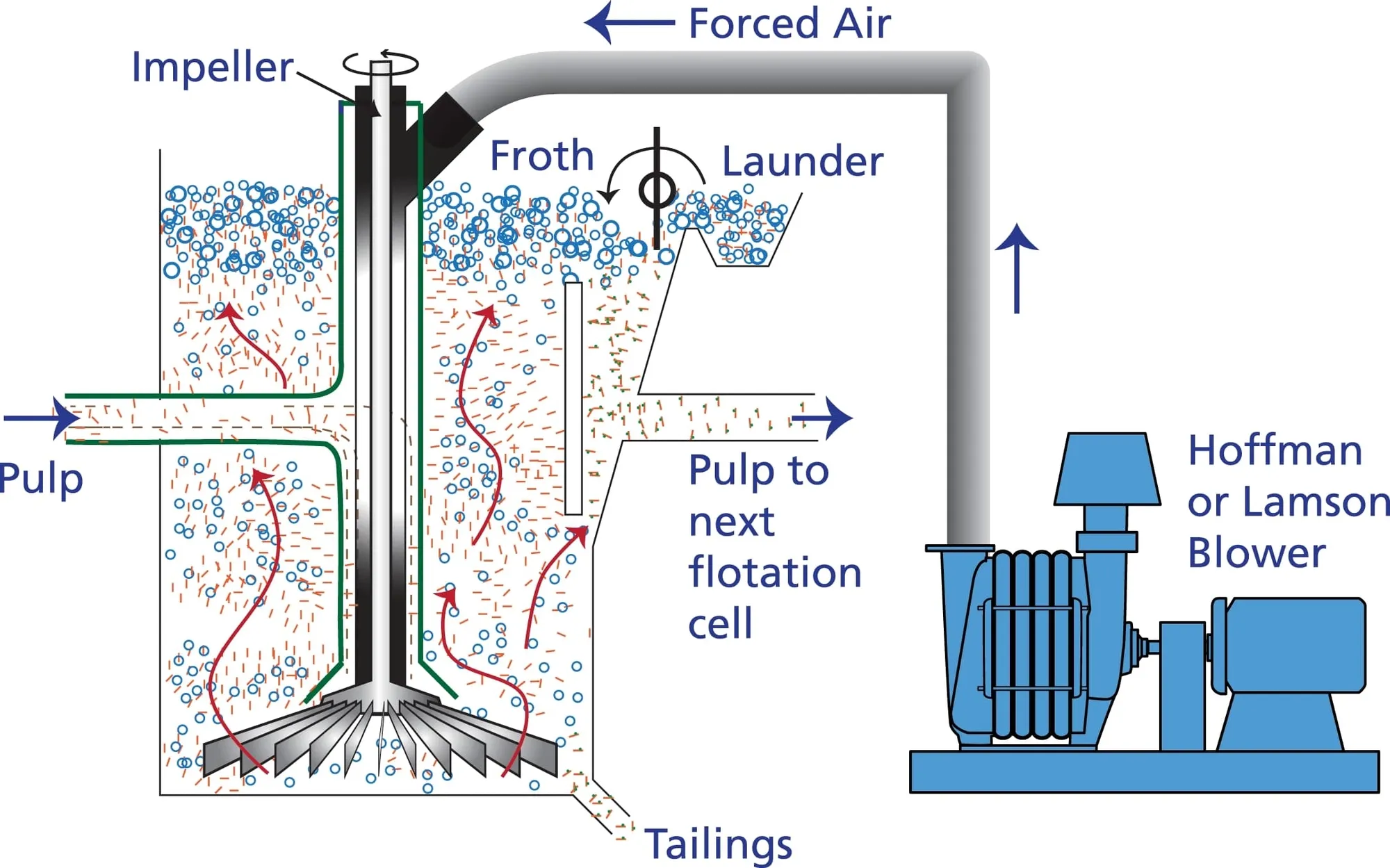

This slurry (called pulp) of hydrophobic particles and hydrophilic particles is introduced to flotation cell tanks that are aerated to produce bubbles. The hydrophobic particles attach to the air bubbles, which rise to the surface, forming a froth. The froth is removed from the cell, producing a concentrate of the target mineral.

Froth flotation efficiency is determined by a series of probabilities like those of particle-bubble contact, particle bubble attachment, transport between the pulp and the froth, and froth collection into the product launder. In a conventional mechanically-agitated cell, the volume occupied by air bubbles is low (5-10%), and the bubble size is usually greater than 1 mm. This results in a relatively low interfacial area and a low probability of particle bubble contact. Consequently, several cells in series are required to increase the particle residence time, thus increasing the probability of contact.

Frothing Stages